Commencing the overview about precise topical improvement processes designed for manufacturing branches

Securing consistent achievements across a production actions? Fineness polishing solutions perform as necessary for realizing outstanding element standard additionally heightened performance. Our service supply a vast variety encompassing cutting-edge approaches, featuring chemical polishing, material smoothing, together with metal shaping, helping to cope with even the most required functions. The capable specialist team coordinates with consumers to formulate fitted polishing blueprints intended to enhance material qualities and confirm precise wholeness. Ultimately, these exact systems contribute to reduced charges and amplified productivity for your firm.

Primary Fusion Sanitation Practices & Gear

Accurate braze purging is unequivocally important for achieving the soundness of any created link. Such operation removes contaminants, porosity, and other foreign materials that can undermine stability. Different methods exist, including physical cleaning with scaler tools, and energy-based abrasion. Specific devices, such as movable automated rotators, needle removers, and weathering procedures, are frequently used for more thorough results, particularly on expansive welds. In addition, reactive mixtures can be implemented to further extract stubborn impurities. Choosing the best technique and relevant devices depends on the weld composition, extent, and expected look.

Pertinent Issues:

- Assembly Assessment

- Weld Study

- Joining Risk Management

Shaping De-Flashing: Techniques & Equipment

Reaching a smooth, functional exterior layer on molded parts is crucial, and burr extraction plays a vital task in that process. Formerly, this was a manual, workforce-demanding task, but modern metal production operations increasingly leverage advanced burr-reducing methods. These processes range from simple hardware brushing and grinding to sophisticated automated systems employing programmable deburring devices and even abrasive spraying techniques. Ultrasonic refinement offers a non-destructive solution for delicate components, while spark deburring is frequently used for strengthened compounds. The selection of the appropriate refinement method depends significantly on the matter, part outline, and desired smoothness. Moreover, understanding the root cause of burr formation—often related to impression design or shaping parameters—can help reduce them altogether.

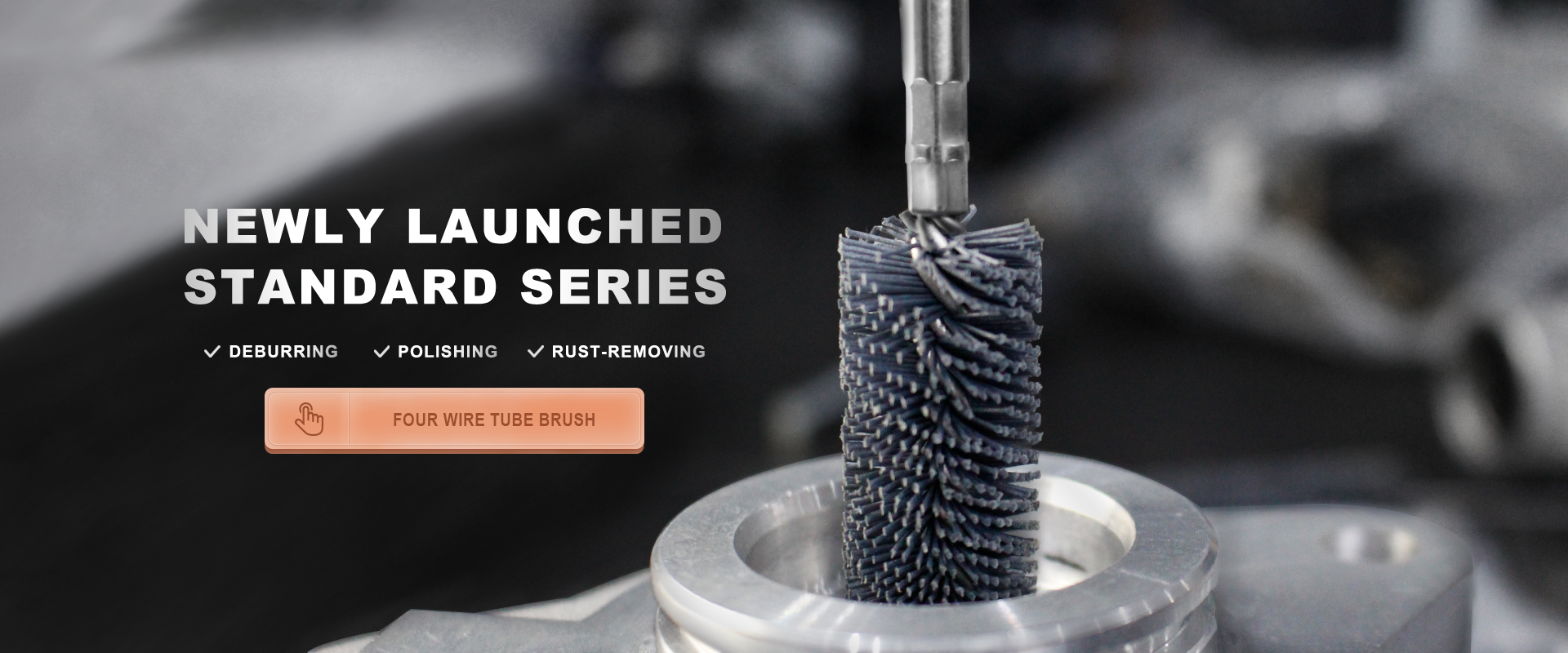

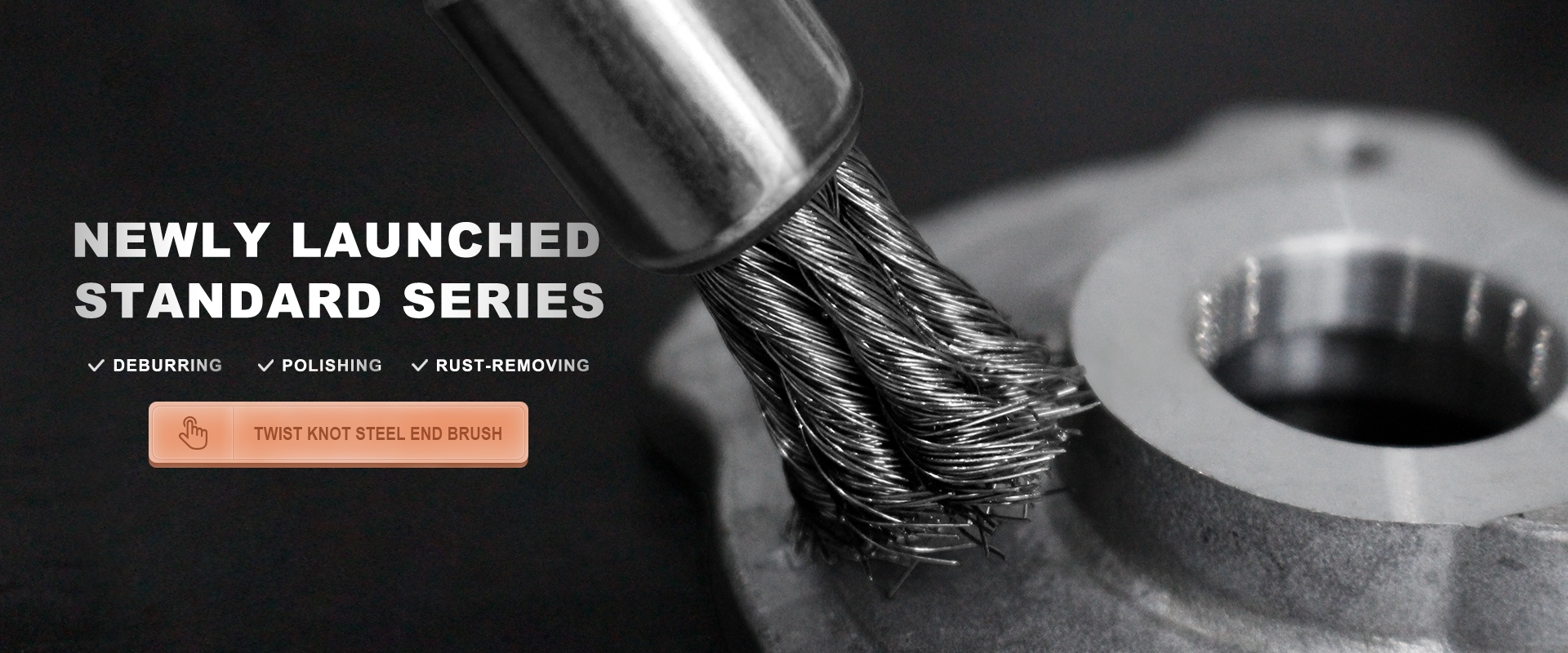

Charged Strip Brush Applications

Conductive refining strip brushing systems find wide-ranging utility across a span of industries, largely due to their gentle yet effective action. Specifically, they excel in removing intricate burrs from stamped metal sections, preparing faces for subsequent plating processes like powder finishing. Beyond deburring, these brushes are frequently used for rigorous surface preparation prior to welding, offering a superior alternative to abrasive tactics that can introduce surface blemishes. Furthermore, their ability to thoroughly remove scale and oxides makes them valuable in restoration operations on industrial equipment.

Top Refinement for Indispensable Components

Performing best performance and extended longevity for majestic machine parts frequently necessitates expert surface refinement processes. This isn't merely about aesthetics; it’s about altering the subtle structure of the compound to reduce coefficient enhance degradation resistance, and improve final functionality. Sundry approaches, including glazing, covering, and optical texturing, can be deliberately applied depending on the specialized application and the expected outcome. The selection of a chosen refinement method must always consider the substance's properties and the executing environment to avoid unintended consequences and improve the component's robustness.

Machine-driven Seam Descaling Platforms

The impetus for consistently high-quality welds in modern assembly environments has spurred significant advancements in solder post-processing techniques. Automated purification frameworks are rapidly gaining popularity as a answer to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced tools often incorporate technologies such as laser treatment, high-pressure waterjet jetting, or specialized abrasive particles, ensuring efficient and precise remnants removal without damaging the underlying fusion. Implementing these digitized solutions leads to reduced human-resource costs, improved well-being, and a more consistent surface that directly impacts the structural integrity integrity of the final assembly. The ability to integrate these platforms into existing making lines further enhances their appeal across a wide range of industries, including aerospace and heavy machinery.

Finishing Forms for Ultimate Performance

For the purpose of reach maximum findings from your fabrications, deburring is a vital procedure. Protrusions, a recurrent byproduct of the assembling routine, can hinder operation, cause performance threats, and harmfully weaken facial aspect. Therefore, in-depth deflashing – which may involve operated means or intelligent systems – is imperative for delivering a high-quality finished product ready for its destined duty. This measure purely elevates capability but also diminishes the conceivable for collapse.

Exact Sterilization with Blade Scrubbing Methods

Achieving exceptional clarity in rigorous engineering areas often requires dedicated approaches. Strip sweeping approaches offer a potent approach to eliminate dust from sophisticated zones. These cutting-edge systems utilize purpose-built applicators to provide steady application – crucial for thorough disinfection and confirming component level. Think about the benefits of brush brush practices for your next detoxification task.

Cathodic Cleaning for Welds & Surfaces

Ionized polishing offers a influential method for cleaning welds and various surface sorts. This process, fundamentally applying electrochemistry, removes oxides, scale, unused welding fumes, and other residues that can interfere with successive processes like painting, examination, or further fabrication. Unlike abrasive strategies, electrolytic polishing provides a tender action, minimizing degradation to the base material and leaving a remarkably unblemished surface. It's especially beneficial for complex contours and inaccessible areas where manual abrasion would be unsuitable. A carefully adjusted electrolyte fluid and electrical energy are vital for achieving regular results.

Innovative Manufacturing Deburring Strategies

Exceeding traditional manual deburring, modern casting facilities are increasingly employing developed processes to achieve superior edge finishing. These state-of-the-art deburring strategies often involve a combination of automated processes and precisely controlled criteria. Electrochemical deburring, for instance, offers exceptional accuracy and allows for elaborate geometries to be flawlessly cleaned, minimizing fabric removal and maximizing product integrity. Furthermore, programmable deburring cells, utilizing oscillating tools, are becoming universal, providing increased throughput and constant results, particularly for large-scale production runs. The selection of the appropriate polishing method depends heavily on the shaping material, element geometry, and desired condition characteristics.

Sophisticated Detailed Smoothing and Strip Scrubbing Process

The sustained pursuit of surface integrity in modern manufacturing demands ever more tailored systems. Among these, precision finishing utilizing linear scrubbing process stands out as a efficient solution. This approach, frequently employed across diverse industries like aerospace, offers distinct advantages in achieving even material depletion, glossing, and detailing results. Unlike traditional methods, strip cleaning technology allows for highly controlled material ablation and the ability to access demanding geometries with a scope of accuracy previously unattainable. Furthermore, advancements in thread selection and motion engineering continue to expand the functions of this significant coating system.

machine tool industrial brush

machine tool industrial brush