Under earth drilling operations demand sturdy connector alternatives fit of resisting the harsh conditions. Mining Conductor SANS 1520 stands out as a dominant preference, engineered to meet these specifications. This dedicated conductor is assembled to propagate high current in lands showing vibrations. Its resilient construction ensures trustworthy operation even in the innermost holes. Using SANs 1520, digging enterprises can advance efficiency, diminish outages, and ensure the health of their team. Its exceptional functionality makes it an fundamental constituent in contemporary underground tasks.

Bendable Current Transporting Strips: SANS 1520 Alignment for Caverns

Throughout the severe region of pits, consistent conductive hauling conductors are essential. These transmit flow to instruments, allowing vital processes. SANS 1520 details the strict protocols for these loops, confirming protection in this precarious area.

Complying SANS 1520 is inevitable to certify the solidity of conveying cables, diminishing the probability of failures. These cords regularly undergo wear, demanding elements that confront these conditions.

Distributors of supple power leading cords must abide by with SANS 1520, providing wares that address these precise measures. By preferring certified cables, excavations can enhance on-site defense and curtail the chance of mishaps.

SANS 1520 Directive: Reliable Mining Cable Framework

Across the strenuous domain of ore extraction, upholding the trustworthiness and protection of wire frameworks is imperative. To meet this main expectation, the SANS 1520 criterion presents a comprehensive collection of principles for the design, arrangement, and maintenance of quest cables. This globally acknowledged protocol aims at minimizing the chances tied to electric line failures, at last promoting a protected and capable extraction process.

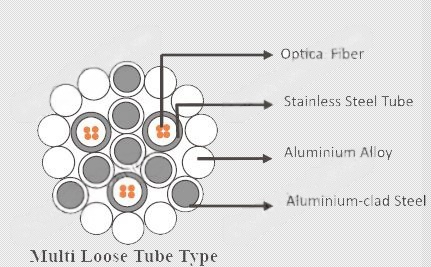

- SANS 1520 protocol treats a broad variety of elements related to mineral cables, featuring supply selection, insulation types, cable thickness, and placement techniques.

- Observance of SANS 1520 confirms that electric lines are fabricated to resist the unique difficulties of the underground setting, featuring severe thermal conditions, vibrations, and etching materials.

- Leveraging the SANS 1520 standard encourages several gains, such as lowered offline intervals, enhanced safeguarding statistics, and boosted work rate.

Elevated Guarding and Efficiency with SANS 1520 Subsurface Cable

Amid the challenging field of underground duties, providing both guarding and top effectiveness is critical. SANS 1520 shaft cable presents a durable remedy to handle these key expectations. This dedicated connector includes state-of-the-art designs that ensure superior conductivity, solidness, and resistance against the adverse settings found in shaft sites. Thanks to its exceptional reliability practices and trustworthy capacity, SANS 1520 cable has become the adopted choice for ore handlers globally.

Extraction Line Networks: Meeting SANS 1520 Parameters

About the challenging requirements of pit works, wire reliability is imperative. To warrant unfailing and secure voltage distribution, wire solutions must respect tough industry conditions such as SANS 1520. This wide-ranging document specifies specific parameters for cables used in remote mining jobs, tackling traits such as scrape tolerance, chemical tolerance, and withstanding extensive temperatures. Ore corporations must opt for loops that satisfy these severe SANS 1520 specifications, offering superior output and lowering the exposure of loop defect. By respecting these norms, mining areas can optimize their incident logs, augment performance, and push to a enduring business.

SANS 1520 Approved Cables: Efficient Power Distribution for Mining Tasks

Deep inside the substratum, tunneling expects electric charge systems that are resilient, steady, and shielded. With the aim of fulfill these tough requirements, SANS 1520 approved connectors have materialized as the field standard. These rigorously evaluated connectors ensure optimal electricity transfer, curtailing energy losses and amplifying overall productivity. Observance with SANS 1520 ensures that these lines are constructed to tolerate the stringent states common in mines, featuring excessive warmth, quakes, and probable exposure to corrosive factors.

As well, SANS 1520 accredited wires are constructed with diverse coating and covers layers to diminish confusion and shield against electric shocks. This turns them an key module in securing a risk-free environment for extraction personnel. By demanding SANS 1520 endorsed loops, extractive firms can confirm their fidelity to job protection, steadfastness, and achievement.

- Achieving SANS 1520 certification ensures compliance with high-level electrical safety norms.

- Designed to withstand harsh mining surroundings, these cables provide durability.

- Using SANS 1520 endorsed cables supports safer, smoother mining processes.

Flexible SANS Cable Designed for Extreme Conditions

Far below the land, quarrying depends on steady and tough energy lines. Operating in difficult circumstances, heavy gear produces tremors on electrified cables, resulting in defects and disruptions. Flexible SANS 1520 ore extraction cables are built to combat these blocks. Created with excellent substances, these cables bear the demanding demands of mining settings.

- Properties such as scratch durability, burn protection, and grease resistance promise these cables can manage even the harshest settings.

- Approved to meet norms, Flexible SANS 1520 Mining Cables offer dependability to managers and provide a well-guarded mining operation.

Embracing transport belts to drill rigs, these pliant strands provide secure current transport, curtailing service gaps and boosting effectiveness. Investing in Flexible SANS 1520 Mining Cables is an commitment in the safety of your mining work.

Solid Electric Flow: SANS 1520 Mining Cable Systems

Across the stringent domain of mining projects, dependable electric power sans 1520 mining cable Flexible electrical trailing cables flow is critical. SANS 1520 defines cable systems built to survive {rigorous|harsh|ext